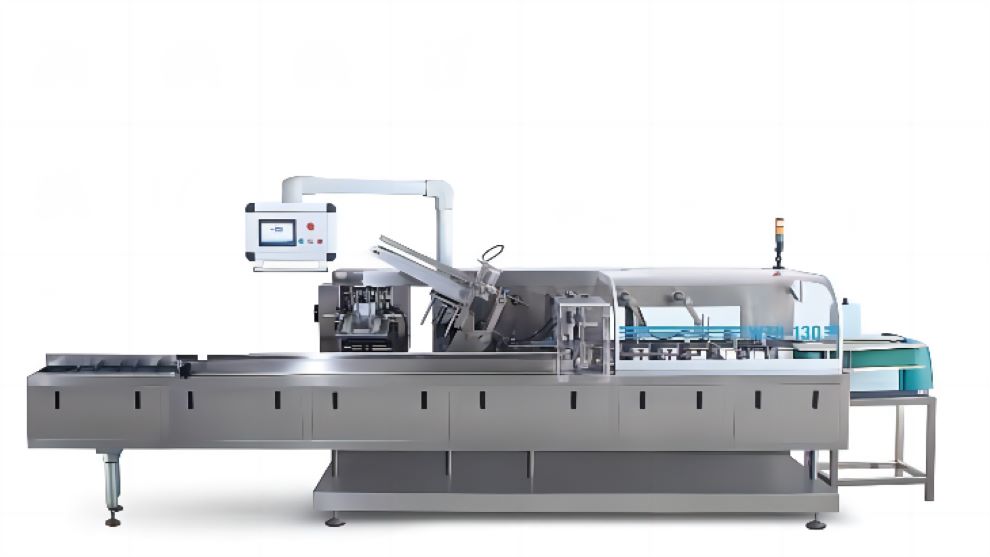

Automatic Cartoning Machine WZH-130

Automatic Cartoning Machine WZH-130

WZH-130 full-automatic cartoning machine is a high-tech product integrating light, electricity and gas. Its reasonable structural design, stable performance and easy maintenance are favored and praised by various industries. Now the equipment is widely used in: pharmaceutical industry: Oral liquid into the refill box, ampoule into the carton box, vial into the carton box and boxed box; food industry: biscuits, cakes, wine, cold drinks, milk powder and sauces; make-up and health care: care solution , eye wash Etc. and daily necessities, hardware and other fields.

Performance characteristics

- It adopts the packaging forms of automatic feeding,unpacking,entering,batch numbering,sealing,rejecting,etc.The structure is compact and reasonable,and the operation and adjustment are simple;

- Using servo/stepping motor and touch screen, PLC programmable control system,the display operation of the man-machine interface is clearer and easier the degree of automation is high,and it is more humanized;

- The photoelectric eye automatic detection and tracking system is adopted,and the empty package can not be dropped into the box which saves the packaging material to the greatest extent;

- Large packaging range,convenient adjustment,and rapid conversion between various specifications and sizes;

- The specification can be changed without changing the mold,and it can be achieved by adjustment. The PLC automatically displays the cartoning speed and finished product count.

- It adopts automatic shutdown of items into the box and overload protection device of main drive motor,which is more safe and reliable;

- According to customer requirements,the use of flip-up safety shield,easy to operate,beautiful appearance.

- Can be linked with aluminum plastic packaging machine,pillow packaging machine,three-dimensional packaging machine, bottling line filling machine,labeling machine,inkjet printer,online weighing instrument,other production lines and other equipment;

- Various automatic feeders and box-in systems can be designed according to packaging requirements;

- According to customer requirements,hot-melt adhesive machine can be equipped with hot-melt adhesive spray sealing box and mechanical brush sealing box.

| Cartoning speed | 30-60(Box/min) | |

| Box | Quality requirement | 250-450g/m²【Base on carton size】 |

| Dimension range (L×W×H) | (80-260)×(40-160)×(15-90)mm | |

| Instructions | Quality requirement | 60-70g/m² |

| Unfolded leaflet specification (L×W) | (80-250)×(90-170)mm | |

| Fold range (L×W) | 【1-4】(Fold) | |

| Compressed air | Working pressure | ≥0.6mpa |

| Air consumption | 120-160L/min | |

| Power | 380V 50Hz 1.5Kw | |

| Overall dimensions(L×W×H) | 4500×1360×1750mm (Customizable) | |

| Weight | About 1800kg | |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.

Capsule Production Solutions

HiF Machine provides cutting-edge capsule production machinery, ensuring efficient and reliable manufacturing processes for the pharmaceutical industry worldwide.

Tablet Production Solutions

HiF Machine offers robust and precise tablet production machinery, tailored to enhance efficiency and reliability in pharmaceutical manufacturing.

Softgel Production Solutions

HiF Machine delivers top-tier softgel production solutions, ensuring high efficiency and consistent quality for pharmaceutical manufacturers globally.

Liquid Packaging Solutions

HiF Machine provides state-of-the-art liquid packaging solutions, designed to maximize efficiency and accuracy in pharmaceutical packaging.