Softgel Encapsulation Machine

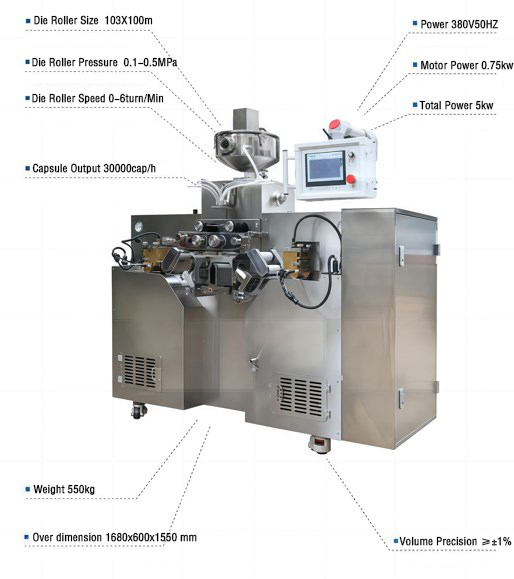

Softgel Encapsulation Machine RJWJ-15

RJWJ-15 soft capsule machine is the latest soft capsule machine developed by our company based on the original soft capsule machine according to the market gap. The machine has a compact structure, beautiful appearance, stable performance, moderate production capacity, more automated and humanized design, and an hourly output of 30,000 capsules. It is an ideal choice for small and medium-sized soft capsule manufacturers.

Softgel Encapsulation Machine RJWJ-15

Intreduce

RJWJ-15 soft capsule machine is the latest soft capsule machine developed by our company based on the original soft capsule machine according to the market gap. The machine has a compact structure, beautiful appearance, stable performance, moderate production capacity, more automated and humanized design, and an hourly output of 30,000 capsules. It is an ideal choice for small and medium-sized soft capsule manufacturers.

Feature

- The gelatin box uses a liquid level sensor and automatic liquid level control.

- The whole machine heating device uses a new temperature control system, and the temperature control is accurate and stable.

- The mold diameter is 103*100mm, and the soft capsule output is stable. It can be used as a research and development equipment or mass production.

Precise filling quantity - Electrical components and electric control boxes use French Schneider or Delta. PLC control and touch screen, electric control components are all imported devices, so that the electric control system has excellent control stability and performance, thereby ensuring the various indicators of the soft capsule machine.

ZL200 Intelligent Softgel Tumbler Dryer

Principle

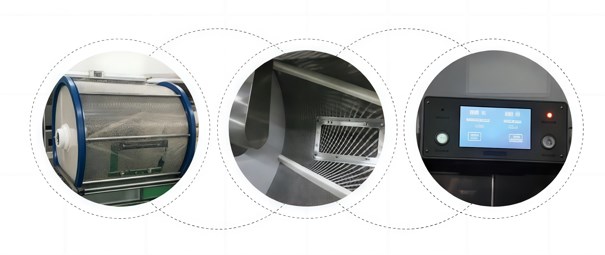

This device combines the principles of typical rotary cage and wheel dehumidifiers, featuring an optimized smart drying cage. It performs dehumidification, polishing, and drying. A touchscreen and PLC control humidity and temperature settings over time, monitored by sensors. Air circulates through the capsules, removing moisture, cooled and further dehumidified before returning, maintaining a controlled environment within the cage. This setup ensures effective and intelligent control of the drying process, minimizes contamination risk, and saves energy. Capsules are automatically transferred between cages after set times, passing through multiple units (each with its own PLC) until reaching the final discharge cage after 10-16 hours. The system is coordinated by a touchscreen or PC, which stores settings for different products, allowing quick setup for repeat productions.

Feature

- Manual state. There is a manual/automatic button on the touch screen. Click the button, and all the forward and reverse rotations of the entire line are manually controlled. However, the temperature inside the cage is automatically controlled.

- Automatic detection alarm and protection function. The touch screen has an alarm record

(1) Phase error and phase loss automatic power off alarm function. Touch screen prompts

(2) Cooling water pressure is too low alarm function. Touch screen prompts

(3) Compressed air pressure is too low alarm. Touch screen prompts

(4) Cage high temperature alarm and protection function. The touch screen prompts and turns off the dehumidifier regeneration heating. The dehumidification and heating will be restarted when the temperature returns to normal. - The overhead transmission mechanism allows the cage to achieve complete isolation between the upper and lower layers to avoid oil leakage and is easy to clean.

- The overhead LCD screen displays the temperature and humidity in each cage, as well as the operating status. Sound and light alarm in case of failure.

- Swedish Proflute rotary dehumidifier, PPS silica gel rotary wheel diameter 450mm, dehumidification capacity: 3Kg/h, including electrostatic oil filter.

- Induction door suction, induction lighting

RJWJ-LQ High Speed Emulsifying Machine

RJWJ-LQ emulsifying shearing system realizes emulsification, dispersion, dissolution and homogenization from simple mixing requirements. With the special design of impeller and inducer, it can quickly dissolve and homogenize colloid powder, sugar-containing materials and liquids.

Sketch Map

1. Stator 2. Nut 3. Spring washer 4. Flat washer 5. Rotor 6. Pump chamber 7. Mechanical seal (static ring) 8. Mechanical seal (dynamic ring) 9. Mechanical seal (static ring) 10. Seal cooling seat 11. Pump base 12. Pin 13. Pump shaft 14. Motor 15. Support foot 16. Frame

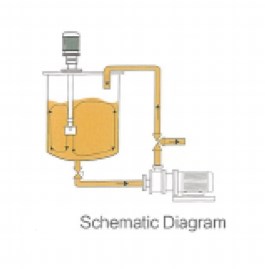

RJWJ-PY Medicine Stirring and Preparation Tank

This series of open stirring liquid preparation pot is a supporting equipment for the process of liquid preparation, precipitation and mixing in the capsule production process. It has jacket type and heat preservation type.

RJWJ-JM Colloid Mill

The RJWJ-JM series colloid mill is used for emulsifying, homogenizing, dispersing, and grinding various emulsion materials. It’s suitable for industries like pharmaceuticals, food, and cosmetics. The mill features a compact design, good sealing, stable performance, and is easy to operate. It’s ideal for processing fine materials. Parts in contact with the material are made of high-strength stainless steel, including the key grinding discs, which are heat-treated for corrosion and wear resistance, ensuring the materials remain clean and hygienic.

RJWJ-RJ-type stainless steel water-soluble sol cans

This equipment is a professional equipment for the capsule pharmaceutical industry. Its main functions include gelation, batching, vacuum processing and condensation.

The features of this equipment include:

- It adopts a water bath type dual-machine multi-layer split flow mixing system to ensure smooth operation and stable work.

- The mixing components are connected by a slip-on coupling, which helps to achieve better homogenization.

- The main body of the equipment is made of stainless steel, which is durable and easy to clean.

- The tank body is designed as a three-layer structure (inner tank, heating layer, insulation layer), and is heated by circulating hot water to speed up the heating process and maintain the temperature, which helps to improve the quality and melting speed of the glue.

- The inner tank adopts a closed design, with excellent vacuum performance and meets GMP hygiene standards.

RJWJ-RJ Gelatin Melting Bucket

This series of sol barrels are special supporting equipment for the production processes of sol, liquid mixing, batching, vacuum, etc., which are necessary for the small-batch production of soft gel pellets.

RJWJ-BW Gelatin Service Tank

RJWJ-BW glue liquid insulation barrel adopts flat glue feeding method. Constant temperature automatic control is safe and stable, and reduces the requirements for factory buildings.

RJWJ-RS circulation hot-water bucket

RJWJ-RS type circulating hot water barrel is a necessary equipment to provide 80°C-100°C hot water source for the sol pot for circulation use. Its process requires the use of hot water exchange heating to ensure the viscosity of the glue liquid in the pot. It is divided into two forms of steam and electric heating.

RJWJ-RLS vacuum condensate jar

This equipment can solve the problem of liquid viscosity uniformity in the production process of chemical glue. It is an energy-saving special supporting equipment that can ease the vacuum negative pressure balance and condensed water collection and control.

ZL200 Intelligent Softgel Tumbler Dryer

| Product model | ZL200 |

| Dimensions | 2300*1280*1640mm |

| Weight (per unit) | 1400kg |

| Power (per unit) | 12Kw |

| Cage size | 840*900mm; working capacity; 75Kg (per section) |

| Dehumidifier | Swedish Proflute rotary dehumidifier; PPS silica gel rotary wheel; 3.5kg water h |

| Dehumidifier design air flow | 1600 cubic meters/hour volume air change 900 times/H |

RJWJ-LQ High speed emulsifying machine

| Dispersion suspension | Immiscible solids and liquids form a mixture or suspension with smaller particle size |

| Emulsification | Immiscible liquids do not separate with liquids Cream, ice cream, animal fat, protein, silicone oil, light oil, mineral oil, paraffin and wax emulsions |

| Homogenization | Make emulsified and suspended particles smaller and more evenly distributed Cream, condiments, juice, jam, cheese, fat emulsion, toothpaste |

| Thick liquid | Cellular tissue, organic tissue, animal and textile tissue |

| Chemical reaction | Nanomaterials, accelerated inflation, accelerated synthesis |

| Extraction | The vortex extraction |

| Depolymerization | Nano powder, dough powder |

RJWJ-JM Colloid Mill

| Model | RJWJ-JM50 | RJWJ-JM80 | RJWJ-JM100 | |||

| Volume | 50L | 80L | 100L | |||

| Emulsification fineness | ≤2um | ≤2um | ≤2um | |||

| Yield | 0.01-0.05Th | 0.5-1T/h | 0.5-3T/h | |||

| Power | 0.75KW | 1.1KW | 3KW | 4KW | 5.5KW | |

| Voltage | 220V | 380V | 380V | 380V | ||

| Speed | 2900r/min | 2900r/min | 2900r/min | |||

| Outlet diameter | Φ5/8″ | Φ1” | Φ1” | |||

| Inlet diameter | Φ1” Φ1/4” | Φ2” | Φ2”Φ1/2″ | |||

| Cooling water pipe | Φ1/4” | Φ1/4” | Φ1/4” | |||

| Weight | 40kg | 130kg | 200kg | 180kg | ||

| Dimensions | 420×280×700mm | 750×450×860mm | 715×380×650mm | |||

RJWJ-JM Colloid Mill

| Project capacity (liters) | 200L | 350L | 500L |

| Operating temperature | 0-100℃ | 0-100℃ | 0-100℃ |

| Motor Power | 1.5kw | 2.2kw | 4kw |

| Overall dimensions | Φ850x1500mm | Φ950x1700mm | Φ1150x1900mm |

| Mixing speed | 33-50rpm | 33-50rpm | 33-50rpm |

| Weight | 80kg | 120kg | 160kg |

RJWJ-RJ-type stainless steel water-soluble sol cans

| Model | RJWJ-RJ150 | RJWJ-RJ350 | RJWJ-RJ600 | RJWJ-RJ800 | RJWJ-RJ1000 |

| Volume | 150L | 350L | 600L | 800L | 1000L |

| Working temperature: | 0-100℃ | 0-100℃ | 0-100℃ | 0-100℃ | 0-100℃ |

| Vacuum degree | <0.09mpa | <0.09mpa | <0.09mpa | <0.09mpa | <0.09mpa |

| Mixing speed | 35rpm | 35rpm | 35rpm | 35rpm | 35rpm |

| Motor Power | 1.5kw | 2.2kw | 5.5kw | 5.5kw | 5.5kw |

| Over dimensions | Φ850x1700mm | Φ950x1900mm | Φ1200x2150mm | Φ1200x2300mm | Φ1200×2500mm |

| Weight | 250kg | 350kg | 600kg | 700ko | 850kg |

RJWJ-RJ Gelatin Melting Bucket

| Model | RJWJ-RJ60 | RJWJ-RJ100 | RJWJ-RJ200 |

| Volume | 60L | 100L | 200L |

| Motor Power | 3Kw | 3Kw | 3Kw |

| Stirring speed | 33-50 rpm | 33-50 rpm | 33-50 rpm |

| Heating area | 3m² | 5.8m² | 5.8m² |

| Vacuum degree | 0.09 mpa | 0.09 mpa | 0.09 mpa |

| Size of tank | Φ500×940 mm | Φ750×1300 mm | Φ800×1300 mm |

| Weight | 50kg | 70kg | 70kg |

RJWJ-BW Gelatin Service Tank

| Model | RJWJ-BW60 | RJWJ-BW150 | RJWJ-BW200 | RJWJ-BW250 | RJWJ-BW300 |

| Size of tank | φ500x700mm | Φ700x900mm | Φ700x1050mm | Φ700x1100mm | Φ700x1145mm |

| Volume | 60L | 150L | 200L | 250L | 300L |

| Heater power | 1200W | 1200W | 1200W | 1200W | 1200W |

| Weight | 80kg | 120kg | 150kg | 170kg | 180kg |

RJWJ-RS circulation hot-water bucket

| capacity | 600L |

| Operating humidity | 0-100℃ |

| Water heat | 2000kg/h |

| Over dimension | Φ900x2000mm |

| Weight | 400kg |

| Power | 27kw |

RJWJ-RLS vacuum condensate jar

| Model | ZKLN-1A | ZKLN-2A |

| Cooling area | 0.5m | 0.7m |

| Condensing capacity (liters) | 60L | 80L |

| Vacuum degree | 0.09 mpa | 0.09 mpa |

| Over dimension | Φ400x1750mm | Φ400x2000mm |

Comprehensive Solutions

Explore HiF Machine’s extensive lineup of pharmaceutical machinery and packaging solutions, tailored for maximum efficiency and value.

Capsule Production Solutions

HiF Machine provides cutting-edge capsule production machinery, ensuring efficient and reliable manufacturing processes for the pharmaceutical industry worldwide.

Tablet Production Solutions

HiF Machine offers robust and precise tablet production machinery, tailored to enhance efficiency and reliability in pharmaceutical manufacturing.

Softgel Production Solutions

HiF Machine delivers top-tier softgel production solutions, ensuring high efficiency and consistent quality for pharmaceutical manufacturers globally.

Liquid Packaging Solutions

HiF Machine provides state-of-the-art liquid packaging solutions, designed to maximize efficiency and accuracy in pharmaceutical packaging.